Our adventure began with several experiences in the fashion accessories industry, until we eventually chose to devote ourselves exclusively to the customisation of various accessories.

We at G.P.S. decided to structure our business according to the market demands, that is innovation, continuous research, and environmental care.

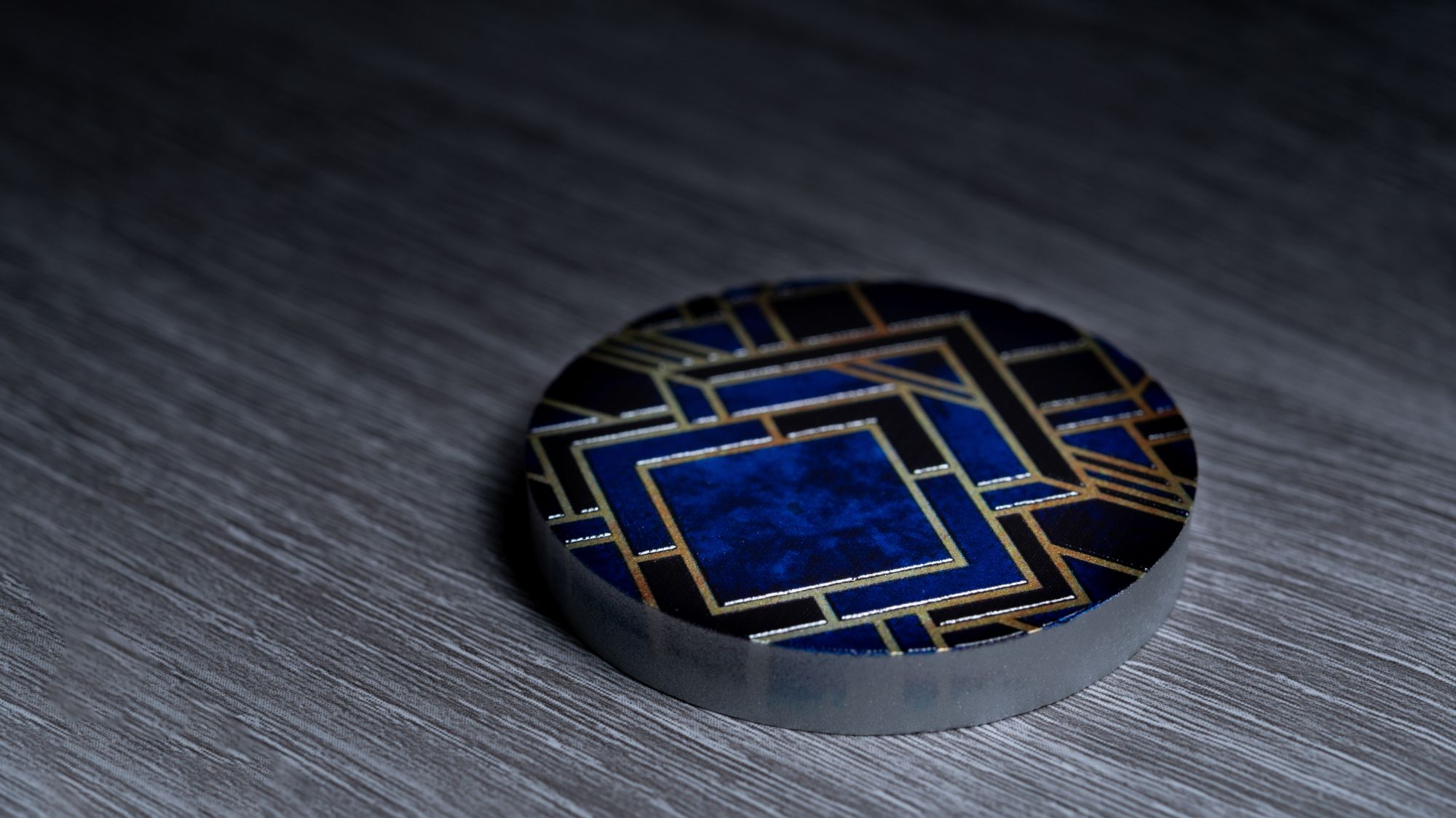

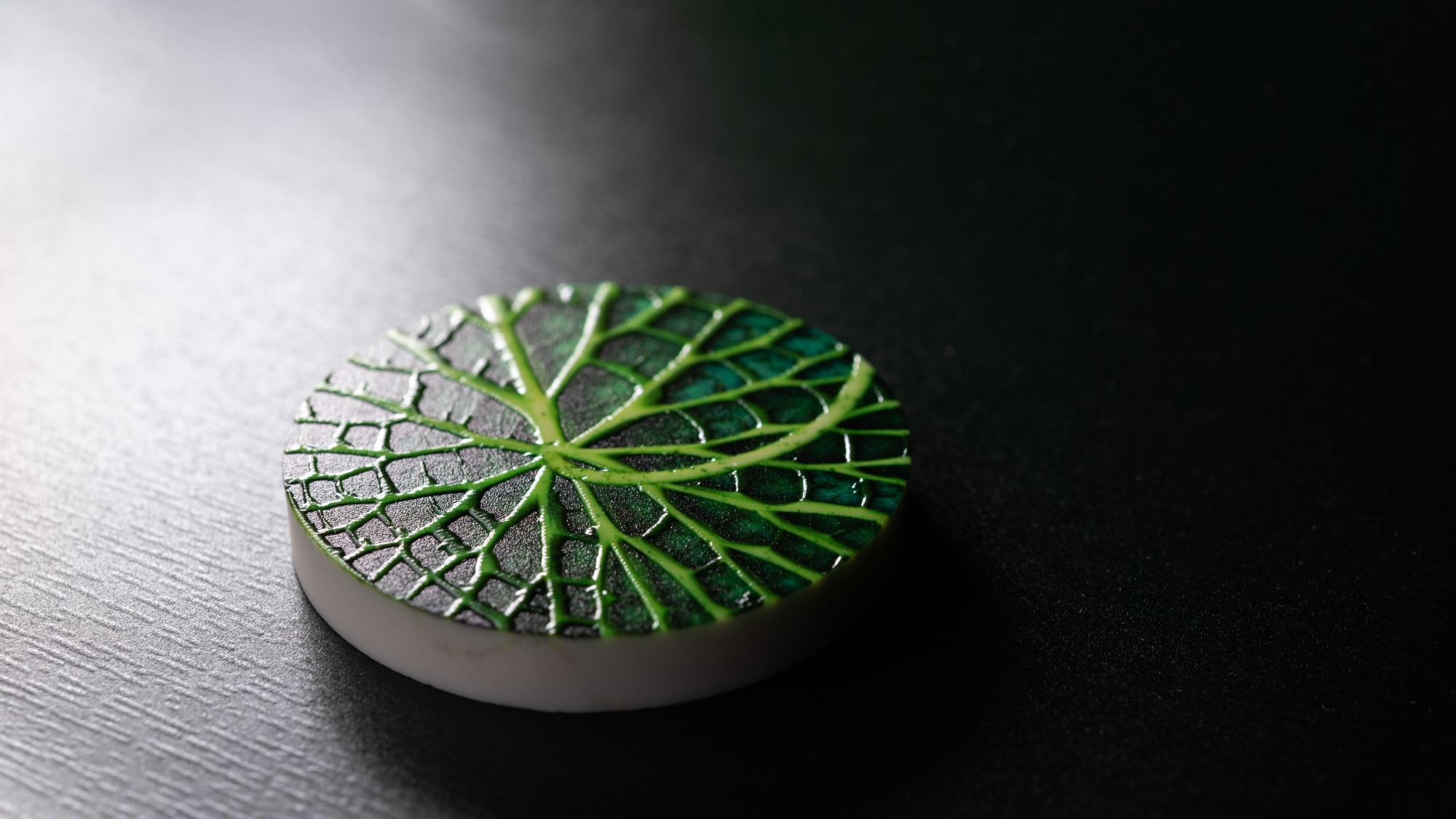

We began by studying how to enhance the elegance of each single button, a product made by many companies in the area, and now we are applying the same concept to an increasingly wide range of articles of different materials and shapes, including application on leather and eco-leather.

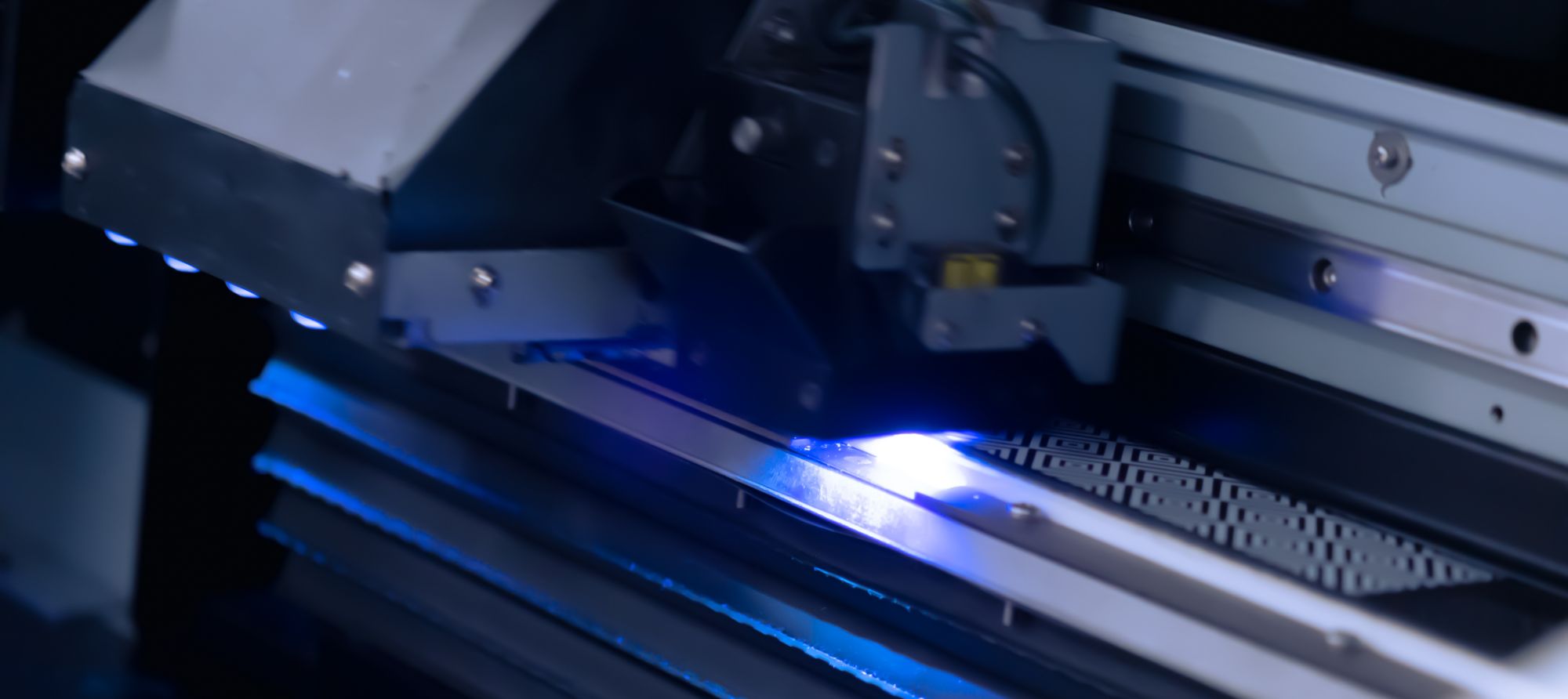

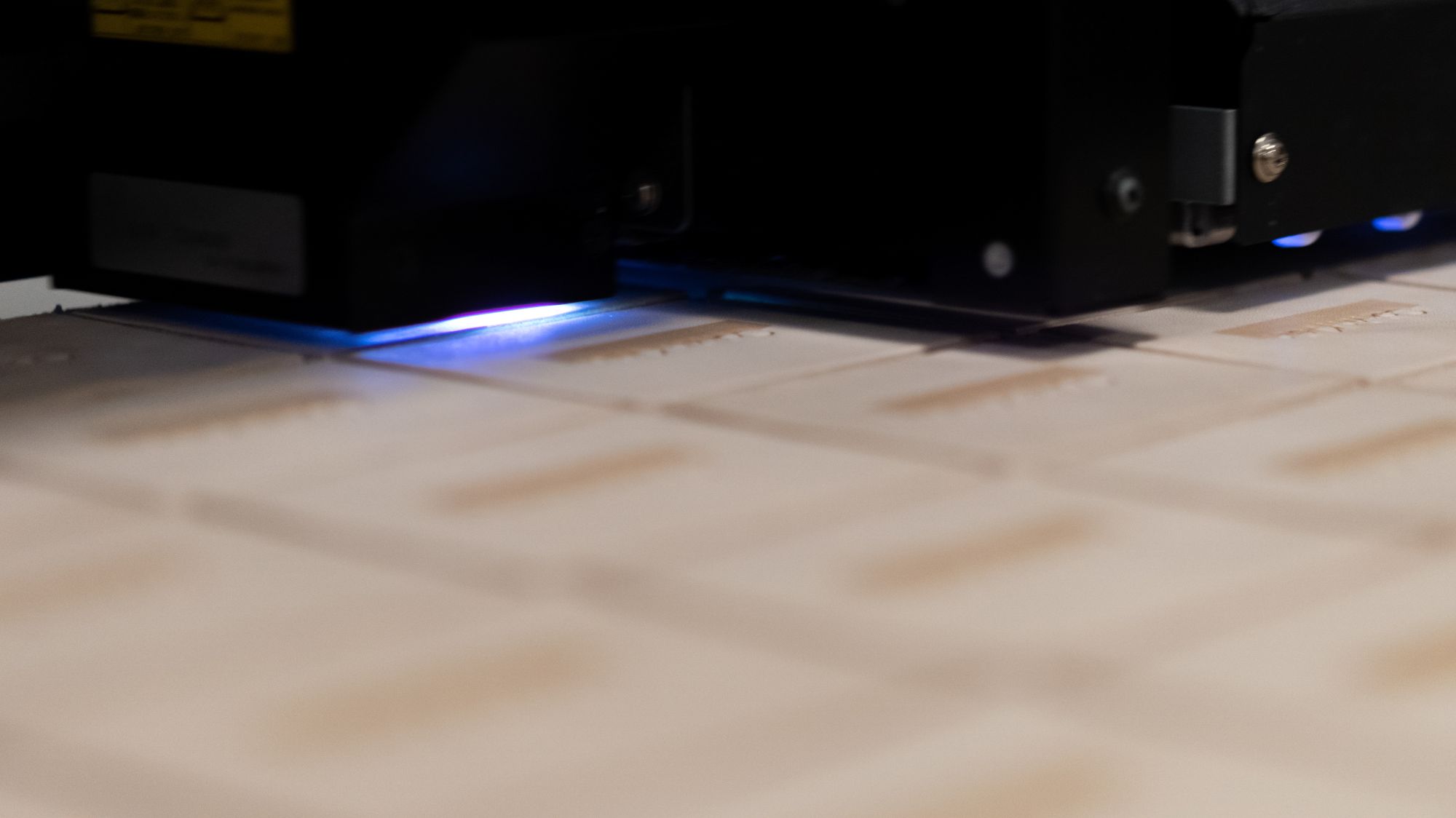

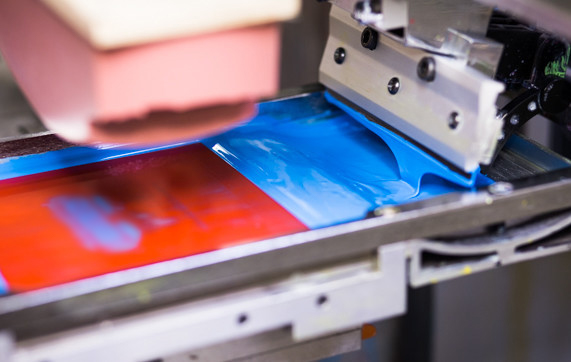

The competitive advantage of our company is provided by constant technological innovation, above all concerning the various printing processes; these make it possible to obtain just in a single process what before was obtained by combining different techniques and steps.

We are always ready and willing to study new projects, supporting the customer at every stage, from design to production.